We are a whole lifecycle technology service platform in power plant for Shanghai Electric (Group) Corp. energy industry chain. Relying on Shanghai Electric's equipment manufacturing and engineering management experience, Huachen Weiye is familiar with the industrial chain from equipment manufacturing, design, procurement and construction to operation and overhaul, can provide high standard and quality comprehensive power engineering services including commissioning and performance test, operation, maintenance, overhaul, and transformation for various types of power plants and transmission projects at home and abroad, to achieve maximum unit operating life and optimize life cycle costs.

Core Strengths

Core Strengths

Power Plant Lifecycle Technology Service Platform

Power Plant Lifecycle Technology Service Platform

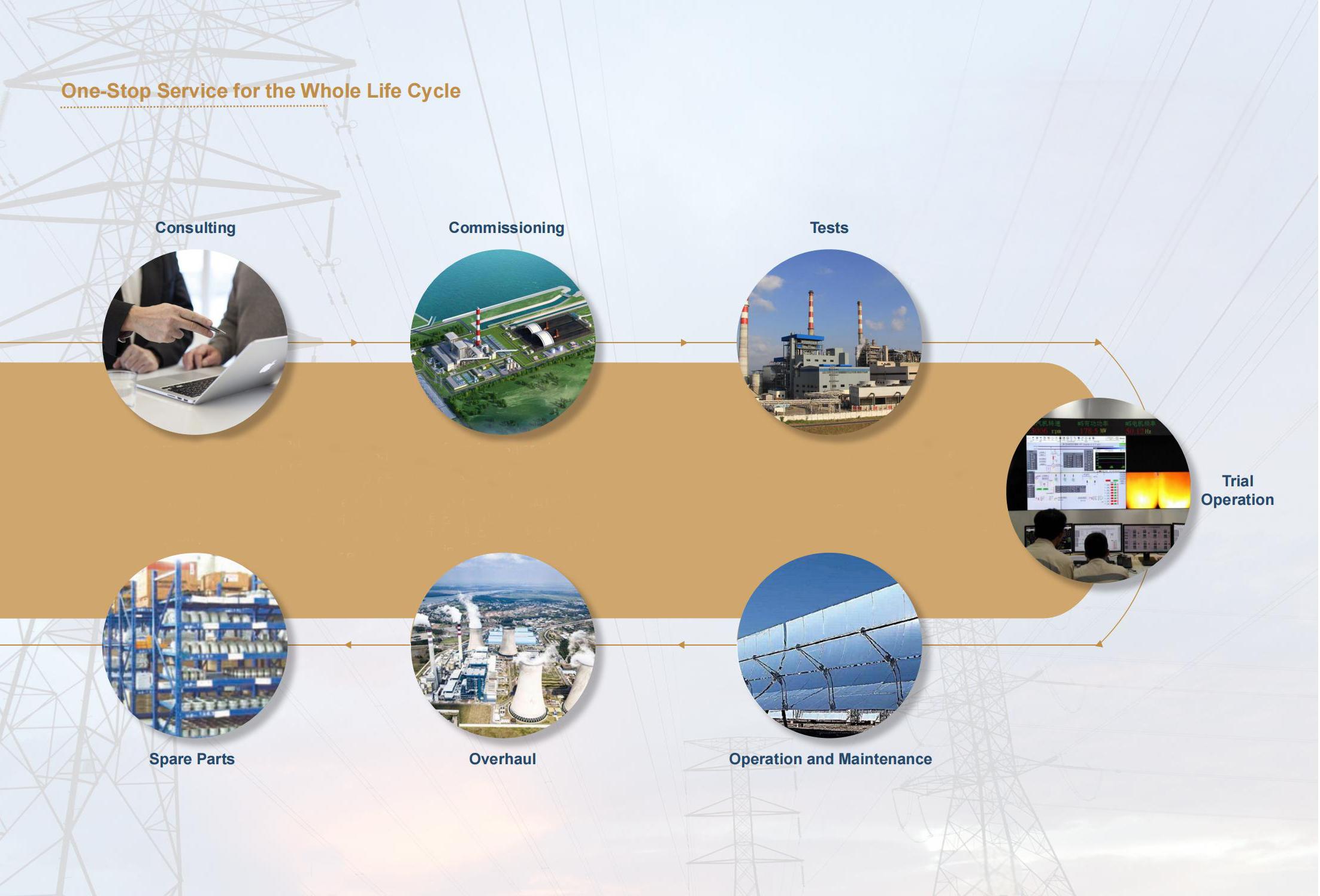

We are engaged in power consulting, power plant equipment procurement, power plant installation and construction, power plant commissioning, power plant testing, power plant commissioning, power plant operation and maintenance, power plant overhaul and technical improvement and power plant spare parts procurement and other related businesses, covering the entire life cycle of power plants.

Comprehensive Business Capability

Comprehensive Business Capability

The company's business includes commissioning, testing and operation and maintenance of various types of power plants, such as traditional thermal power, biomass power generation, garbage power generation, wind power, photovoltaic, solar thermal, energy storage, and regulating camera, etc. Among them, traditional thermal power includes various types of power units at home and abroad, and the Fatima project in Pakistan is the world's largest biomass power generation project, the Dubai Solar Thermal is the world's largest tank-type photovoltaic project, and the Feicheng compressed-air energy storage project is the world's largest compressed-air energy storage project. Feicheng Compressed Air Energy Storage Project is the largest compressed air energy storage project in the world.

Overseas Experience

Overseas Experience

Our company actively develops overseas market, has been in India, Pakistan, Bangladesh, Indonesia, Thailand, Vietnam, Philippines, Malaysia, Zambia, Zimbabwe, Ethiopia, Cuba, Kyrgyzstan, Hong Kong, Macao and Taiwan to carry out various types of technical services, with nearly 20 years of overseas technical services experience, understanding of international standards and owners of the relevant requirements, and can communicate and exchange ideas with foreign owners to understand the needs of the owners, and can more effectively and smoothly complete the project implementation. With nearly 20 years of overseas technical service experience, he understands international standards and owners' requirements, and can communicate better with foreign owners, understand owners' needs, and complete projects more effectively and smoothly.

Professional Talent Team and Advanced Instruments and Equipment

Professional Talent Team and Advanced Instruments and Equipment

Our company has all kinds of technical talents, with all the professional talents who can independently carry out power station commissioning, test run, performance test, special test, operation and maintenance and other power station technical services, and has rich experience in domestic and foreign implementation. The company has all kinds of test instruments to meet the various requirements of commissioning and testing.

Advantage of technical capabilities

Advantage of technical capabilities

Mature FCB technology

Mature FCB technology

After exploring many overseas projects, the company has improved the feed water control scheme, controlled the boiler load, steam engine speed, ladle water level, boiler fuel oil, negative furnace pressure and other parameters, to ensure that when FCB is triggered, the high and low bypass valves will open quickly and adjust the pressure automatically, so that the boiler load will be reduced to a suitable load point, effectively avoiding the MFT caused by the ladle water level, and increasing the success rate of FCB, and ensuring that the whole process does not require manual intervention. This effectively avoids the MFT caused by the water level in the steam ladle, improves the success rate of FCB, and ensures that the whole process does not require manual intervention.

APS one-key start-stop function

APS one-key start-stop function

With the practice of several overseas projects, the company's technical team has conducted a large number of tests on the equipment and logic of the unit, successfully mastered the technical essentials of APS, and realized the APS function of various forms of units, which can reduce the configuration of the operating personnel, reduce operation errors, and effectively improve the degree of automation of the unit.

Coordination control system optimization

Coordination control system optimization

The traditional DCS and its control are optimized to effectively improve the coordination control quality of the unit in the context of deep peaking and wide-load operation, guarantee the flexible adjustment capability of the full-load zone, and enable the unit to meet the requirements of the load change rate of the grid when AGC is commissioned in the wide-load range, and at the same time further reduce fluctuations in the main steam temperature, pressure, and nitrogen oxides, so that it can participate in the deep variable-load operation under safe and stable operation conditions.

Electrical Testing

Electrical Testing

We have the Class II Qualification for test contractor issued by the National Energy Administration, and the electrical test basically covers the electrical handover, overhaul and preventive test projects of substations, photovoltaic power stations, wind power stations, energy storage power stations, photo-thermal power stations, thermal power plants, etc. of the voltage level of 210kV or below, and the handover of power cables of 110kV (up to 1kM), 35kV (up to 5kM), and 10kV (up to 10kM), Overhaul and preventive testing of power cables up to 110kV (1kM), 35kV (5kM), 10kV (10kM), overhaul and preventive testing of generators up to 660MW, testing of lightning protection and grounding devices in power plants, substations and industrial mining units. With the following characteristics test:

※ Generator rotor turn-to-turn short-circuit test technology (repetitive pulse method)

※ Transformer partial discharge detection technology

※ Generator stator core fault detection technology (EL-CID)

New energy intelligent, digital operation and maintenance

New energy intelligent, digital operation and maintenance

With the help of digital technology and intelligent products, we gradually realize less manned and remote intelligent management of new energy stations.